Virtualization is the next step forward in plant environments to minimize server downtime and increase ROI. Traditional servers have numerous single points of failure. Having servers without virtualization can be costly and inefficient PCs and HMIs are prone to failure and can take considerable time to recover with can further reduce OEE. While virtualization has been more common in the office space, plant floor technologies are now being virtualized to further improve operational efficiencies.

What is virtualization?

Virtualization creates a virtual version of a device or resource, such as a server, storage device, network or even an operating system. It began gaining popularity a little over a decade ago but was primarily used in the IT space. However, manufacturers see how virtualization can be applicable in plant floor space as well.

Prior to virtualization, the best practice was to have 1 workload per physical server – because a lot of cross chatter and different patterns with workflow and read/write perspective could interfere with apps. This means on average only 5-10% of the server is fully utilized at one time. Virtualization can serve as a traffic control cop making sure resources are allocated and supported between fewer servers as needed. In a virtualized environment, CPU and memory are resourced more efficiently. This shrinks your physical footprint tremendously, saving power consumption and helps reduce labor and infrastructure needs.

Physical resources are still needed for virtual servers; however, they are much quicker and easier to backup and restore which reduces downtime. The resources are also monitored so storage, memory, and CPU can be directed where they need to be when they need to be. It’s also not just limited to servers and can be applied to desktops with Virtual Desktop Infrastructure (VDI).

Why switch to virtualization?

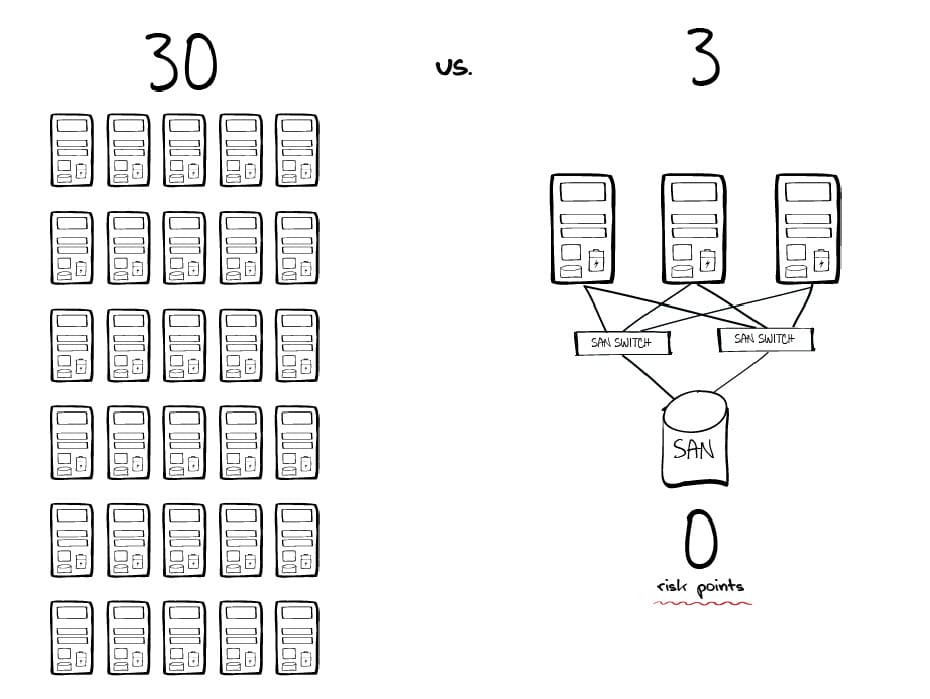

Using virtualization can for example reduce 30 servers with multiple risk points each to 3 servers, with few risk points. By running plant floor applications virtually, recovery time is seconds, not days! This results in fewer refresh cycles, a significant return on investment, and a smaller technology footprint. Virtualization can be scaled as the business needs change and allows the business to allocate storage and memory as needed.

The switch to virtualization in manufacturing is important to stay competitive and adapt as a new generation of tech savvy workers are entering the industry. Virtualization also increases ROI and makes it quick and easy to calculate the benefits. The redundancy built into virtualization also ensures no downtime by allowing the system to continue to work even if something breaks.

What does the process look like?

Before you begin starting the switch, Applied Technologies will first evaluate your current system workload. We have tools to capture all activity ideally for a 30-day minimum to correctly size the plant floor environment. Next, we analyze the physical servers and run diagnostics to determine what specific applications, files, software and tools are being used. We evaluate your current hardware requirements and recommend how we can scale back hardware to run the same plant floor processes in a virtualized environment. We also review your future technology requirements and how you can best use virtualization to scale up as business needs change. Once approved, we set-up the hardware and virtualized environment, test all processes and schedule the migration with your IT/OT team. We have a wide range of pre-sale and post-sale services to help ensure a smooth transition and offer ongoing monitoring of your virtualized environment.

Many companies are virtualized in the “carpeted space” but may not think they can do it on the plant floor. However, virtualization is not new technology, and is simple to implement across both IT and OT spaces.

Why choose Applied Technologies?

At Applied Technologies, we have knowledgeable data and networking engineers who have been helping businesses make the switch to virtualization since the technology originally launched in 2000. We have the know-how to properly transition to and maintain virtual servers, including remote monitoring. Applied Technologies understands the OT space, and how they work in a virtual environment.

Virtualization can bring incredible advances in efficiency and ROI to the plant floor. It can often cost more to recover from downtime than it does to switch to virtualization, meaning the transition quickly pays for itself. If you are interested in virtualization, contact us today so we can discuss the best route forward for you.