The famous line, “If you build it, they will come,” sticks with many. While it inspired Kevin Costner’s Field of Dreams, it’s not the best approach for your smart manufacturing strategy. This mindset likely contributes to the high failure rate of industrial IoT initiatives and the lack of large-scale alignment. In this Q&A, Krista Salvatore, Vice President of Applied Technologies, shares insights on building a connected enterprise strategy that works.

Q: What is a typical automation scenario, and why does it not serve an organization well?

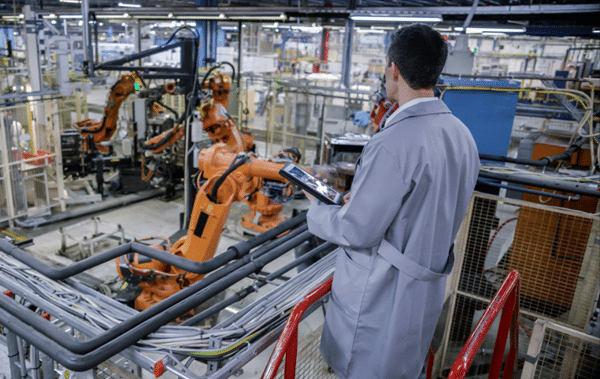

In many industrial facilities, automation is seen as a technology issue. This approach often leads to a siloed, equipment-centric mindset, where a piece of software or hardware is introduced to solve a specific problem. The solution becomes primarily technology-focused, centering on how to make it run. On the plant floor, the operational technology (OT) team focuses on streamlining individual processes or equipment. Traditionally, IT and OT operate separately because they report through different arms of the company: IT through the CFO and OT through plant management and engineering.

This fragmented approach to building a connected enterprise limits success for three key reasons::

- It’s fragmented and typically reliant on the scope of a single piece of technology.

- It’s a bottom-up situation that’s not aligned with the overall strategic objectives of the organization.

- It’s not embraced in a large-scale way across the organization.

Q: How can a comprehensive, top-down approach help to ensure smart manufacturing success?

A top-down approach is always more effective. When leadership drives the connected enterprise strategy, the chances of success increase significantly. Here’s why:

- Leadership sets a long-term vision for extracting business value from technology, aligning it with overall business goals.

- The focus shifts from technology to how it can help achieve the organization’s vision. Technology alone won’t solve challenges or drive the company forward.

- This approach fosters departmental alignment and collaboration, breaking down barriers between IT and OT and encouraging shared ownership of business goals.

- It also initiates cultural change, empowering teams at all levels to contribute to transforming business processes.

Q: What are the key steps that must be taken in order for this to happen?

Start by examining your business needs. Identify gaps and determine where the organization needs to go to stay competitive. Some initiatives will be long-term, but there are smaller, actionable projects you can begin within the next 12-24 months. Leadership should prioritize these initiatives and develop a business change management plan and technology plan to gain traction.

Next, assemble a team to envision the organization’s future state. What will your products look like in five years? Who will you serve? The people closest to the products and processes can best identify these gaps.

Once gaps are identified, assess the potential gains. What will fixing these issues be worth to the organization? You can then begin working on the details in terms of the processes and technology required to arrive at the solution. This brings forward the things that IT people like to talk about, and integrates the things that OT teams like to work on. This is the part in the process that bridges the gap between the two disciplines, and creates cooperation towards a common, organization-wide goal.

Q: What are the dangers of not embracing top-down enterprise strategies for smart manufacturing?

In manufacturing, constant reinvention is essential. If you don’t innovate, your competition will. I like to use the analogy of the buggy. You don’t see buggies anymore because someone came up with a better product: the car! And someday, cars will be replaced by something else. Or, your competitor may identify a way to make your same product better, cheaper, or quicker, causing you to lose market share. Top-down connected enterprise strategy helps the organization to envision what’s next, mapping out how the organization will get there and identifying what processes and technologies will make it happen.

If that doesn’t wake you up to the importance of top-down strategy, consider this. It’s ultimately more expensive to do it the other way around. A bottom-up approach does not breed success, and the chance of choosing the wrong (or outdated) technology solution is high, or the solution chosen is not supported across the entire organization.

A key point to consider: It’s very difficult to end up with a connected enterprise and realize the value of smart manufacturing from a technology perspective with disconnected business processes and or organizations.

Those who embrace this process and forward planning will be the leaders of tomorrow, while the rest risk being left behind – or going the way of the buggy.

Start the Conversation

Ready to discuss your industrial IoT (IIoT) requirements? Contact us today at [email protected] or 636.274.8000.